Welcome To Spink Controls

-

Call Us

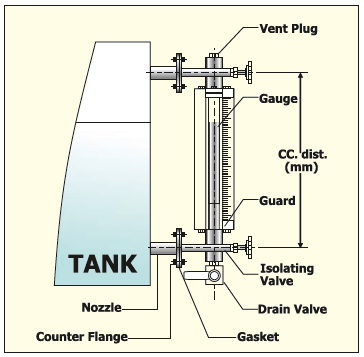

Tubular level Indicator

Manufacturing and Suppliers of Tubular level Indicator

Introduction for Tubular level Indicator

MODEL: SC / L - 001

Gauge is fitted between two end fittings through gland packing. The gauge is mounted parallel to tank so as to form a close loop causing tank liquid to seek its level in the gauge. The Gauge Glass is protected with ‘C’ channel. End fitting has built-in isolating valve, drain valve & vent plug.

Auto Ball Check

Auto ball check facility is provided to prevent "liquid loss" from vessel during breakage of gauge glass. It consists of a capsule located within the gauge neck ' and contains a ' ball which moves freely along its inner race between the stopper & orifice. During breakage, the pressure on 'ball' from gauge side will be atmospheric, whereas higher pressure from vessel side ("optg pr + liquid column") will cause the ball to move and block the orifice, to minimize liquid loss.

Engineering Specification for Tubular level Indicator :

- Gauge : HW Borosilicate Glass 16 / 19mm OD (25mm for Viscous Liquids)

- End Fitting MOC : CS / SS 304 / SS 316 / PP / PTFE

- End Block Type : W / O Valve / Offset NV with or W / O Auto Ball Check

- Guards : CS / SS304 / FRP C- Channels

- Gland MOC : CI / SS 316 / PP

- Packing : PTFE

- Process conn. : 3/4 ” / 1 ” Flanged (Table D / ANSI 150#) or BSP Screwed

- Vent / Drain : Plug / Ball valve

- Scale : Aluminium Engraved

- CC Dist. : 1500mm in Single Length, Large CCD’s thru’ Coupler

- Visibility : CC Dist – 150mm

- Maximum Temp. : 200°C (Metallic) / 70°C (PP)

- Test Pressure : 10 Kg/cm² (Metallic) / 2 Kg/cm²

Installation of Tubular level Indicator:

- Side mounted through tank nozzles, having matching counter.

- Flanges / threads, ensuring that CC distance between nozzles.

- Corresponds with CC distance (R) of the gauge.