Welcome To Spink Controls

-

Call Us

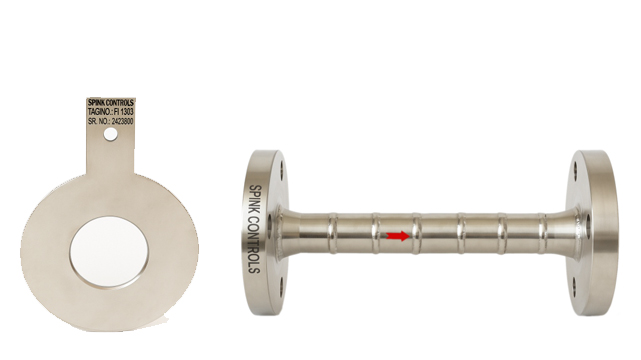

Orifice Plate And Assembly

Manufacturing and Suppliers of Orifice Plate And Assembly

Introduction of Orifice Plate And Assembly

MODEL: SC / R - 800

The Orifice Plate with Flange Assemblies is employed for measuring the flow rate or volume of moving fluids, including liquids, gases, and vapours. These plates are designed according to BS 1042-1981, ISO 5167, and LK Spink standards, offering reliable and accurate flow measurement

Orifice Plate Types: Square Edge Concentric, Eccentric, Segmental, Quadrant Edge, Conical Entrance

Plate Thickness: 3.18 mm, 6.35 mm, 9.52 mm, 12.7 mm standard; other thicknesses available on request

Material Options: Standard materials include SS304, SS316, SS304L, SS316L; additional options like Hastelloy C, Monel, Inconel, Polypropylene (PP), PVC, PTFE, and Stellite coatings are available

Orifice Flanges: Forged type Weld Neck, Slip-On, Threaded, Socket Weld with RF, FF, RTJ facing, rated from 150# to 2500#, higher ratings on request, compliant with ASME 16.36 for sizes up to 8 inches; larger sizes or male-female flanges available as per ASME B 16.5 and ASME B 16.47 series A/B

Technical Specification of Orifice Plate And Assembly :

- LINE SIZE : 15 NB TO 600 NB

- FLANGES : ASTM-A-105/A182 /S 316/SS 314/ MONEL

- OPTIONAL : IBR APPROVED FLANGES

- TYPE OF FLANGES : WELD NECK /SLIPON /SOCKET– WELD

- GASKET : SPIRAL WOUND/CAF/ TEFLON

- TYPE OF TAPPING : FLANGE TAPS /CORNER, TAPS/ RADIUS TAPS

- SIZE OF TAPS : ½ INCH NPT (F)

- STUDS / BOLTS : ASTM-A-193 GR B7

- NUTS : ASTM-A-193 GR 2H

Conditioning Orifice Plate

- The Conditioning Orifice Plate integrates a flow conditioner with an orifice plate, creating a precise primary element that delivers high accuracy in flow measurement

- Reduced Straight Pipe Requirements: Requires only 2 diameters of straight pipe run upstream and downstream from most flow disturbances, saving installation space and costs.

- Versatile Applications: Suitable for gas, liquid, and steam measurements

- Available Sizes: 2" to 24"

Intergral Orifice Plate Assembly

The Integral Orifice Plate Assembly is a precisionengineered flow measurement solution, ideal for applications requiring high accuracy at low flow rates in line sizes below 2’’. It is designed using the differential pressure principle, providing reliable and economical flow measurement for compact installations.

ENGINEERING SPECIFICATION

- Line Size : 15 NB to 40 NB

- Material Options : ANSI 316, ANSI SS 304, Monel, Hastelloy C

- Gasket : PTFE

- End Connections : Socket-weld or threaded ends for compact installation

- Flanges : ASTM-A-105, A182, S 316, SS 314, Monel

- Optional : IBR Approved Flanges for specialized applications

Note: The Conditioning Orifice Plate is ideal for installations with limited straight pipe runs, ensuring performance consistency and minimizing installation constraints

Restriction Orifice

The Restriction Orifice is specifically designed for applications requiring precise pressure reduction and flow control. This orifice design reduces pressure gradually in multiple stages, which is essential for handling high-pressure fluids and gases while minimizing noise and preventing cavitation.

Key Features: Multistage pressure reduction to prevent cavitation and minimize noise.

Engineering Specification

- Applications : Suitable for high-pressure fluid, gas, and steam systems.

- Size : 15 NB to 600 NB ( custom sizes available).

- Materials : SS304, SS316, Monel, Hastelloy C, with PTFE coating options.

- Flange Ratings : 150# to 2500# ( higher ratings on request).

- Standards : M eets international performance and reliability standards.

Note: The Conditioning Orifice Plate is ideal for installations with limited straight pipe runs, ensuring performance consistency and minimizing installation constraints