Welcome To Spink Controls

-

Call Us

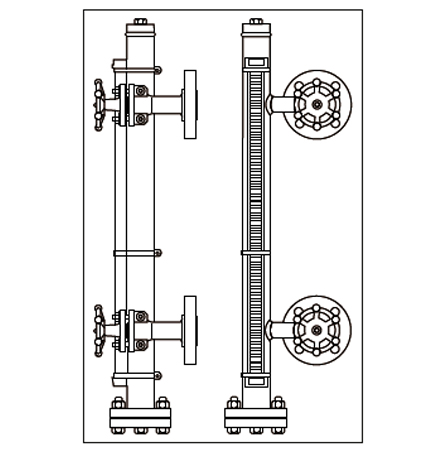

Reflex Level Gauge

Manufacturing and Suppliers of Reflex Level Gauge

MODEL: SC / L - 201

A Reflex level gauge is highly recommended for colorless liquids. They are used in applications involving high temperatures, pressure conditions, and the corrosive nature of fluids. Reflex & transparent level gauges are preferred due to their ruggedness, sturdiness and low initial costs. The industries dealing with the materials that are highly toxic and inflammable, and are used under high pressures and temperatures. The Reflex Level Gauge is one mechanism that is extremely suitable for this industry.

Technical Specification of Reflex Level Gauge :

- Gauge Glass : Toughened Borosilicate (30W) or (34W).

- Liquid Chamber : CS /MS/SS 304/SS 316 .

- Cover Plate : CS /MS/SS 304/SS 316 .

- Process Connection MOC : CS / CS A105/SS 304/SS 316.

- Process Connection : 3/4” or 1”x ASME 150#, 300#, 600# RF

- Process Orientation Connection : Rear-rear

- Isolation Valve : CS A105 or SS316 x Offset Needle Valve

- Vent : ½” NPT

- Plug Drain : ½” NPT Globe or Gate or Needle Valve

- CC Distance : Up to 1000 mm, others on request

- Calibrated Scale : Aluminum/ SS304

- Max.Temperature Operating : 243°C Max.

- Operating Pressure : upto 32 kg/cm² Max.

- Test Pressure : upto 64 kg/cm².

- Gasket : CAF/ Graphoil Reinforced SS 304/ 316 Reinforced.

- Bolts & Nuts : A193, Gr. B7, A194 Gr. 2H.

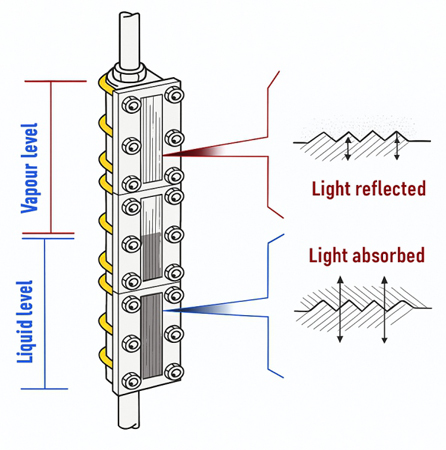

Principle Of Operations :

Reflex level gauges are designed to detect the difference in refractive index of vapor and liquid and level detection and can be used in a number of process applications. This glass is flat on the outside and on the inside has a series of prism grooves that face the vapor and liquid space.

Engineering Specification of Reflex Level Gauge :

- Process Connection Orientation : Rear

- Drain : ½” Npt Globe Or Gate Orneedle Valve

- Vent : ½” Npt Plug

- Cc Distance : 1000 Mm (Other On Request)

- Temperature Rating : 243 °C

- Pressure Rating : 64 Kg/Cm²-G